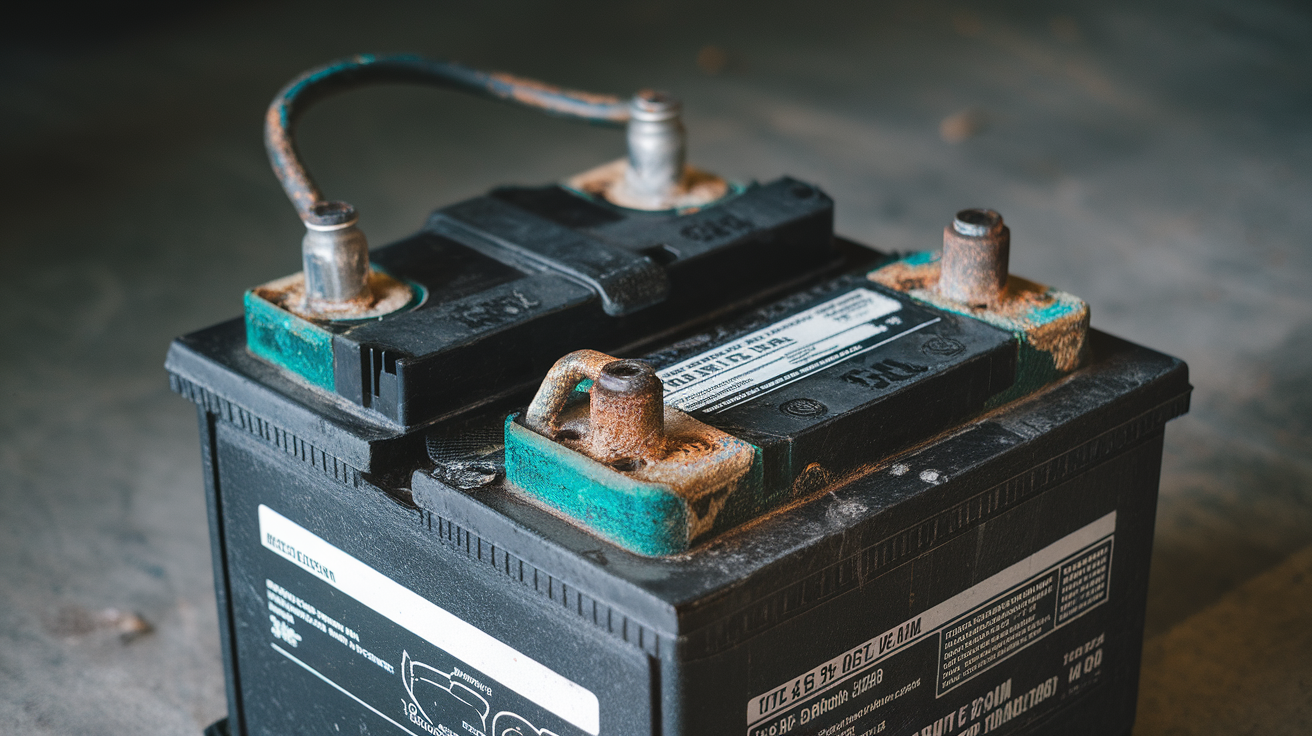

Car Battery Terminals Matter More Than You Think! You press the start button. Nothing. Just a faint click. That’s not a dead battery; it’s often car battery terminals doing what they do best when ignored: corroding. These small connectors carry the charge that powers your ignition, lights, and onboard systems. When corrosion builds up, it blocks electrical flow. Not partially, completely. And in Dubai’s heat, corrosion spreads faster than most drivers expect.

Most people don’t notice until the car struggles to start or throws random electrical errors. By then, the damage may already be creeping into your cables and connectors. If you’re seeing white or green buildup, don’t wait. Terminal corrosion is not just a nuisance; it’s a gateway to bigger electrical problems. We fix this every day. Let’s keep it from becoming your next roadside emergency.

What Are Car Battery Terminals & Why Do They Corrode?

Let’s not sugarcoat it, car battery terminals are the unsung heroes of your vehicle’s electrical system. They’re just metal clamps, sure, but without them, your battery’s power never reaches the ignition, lights, or onboard electronics. And when they corrode, they don’t just look bad; they choke the flow of electricity.

Most terminals are made from lead, copper, or brass. Each material reacts differently to the environment. Lead terminals tend to form lead sulfate, a chalky white crust. Copper clamps? They oxidize into copper sulfate, which shows up as a greenish-blue mess. Brass is more resistant, but not immune, especially in Dubai’s heat, where battery acid vapor accelerates corrosion. Here’s what’s happening under the hood:

- The battery acid reaction releases hydrogen gas

- That gas mixes with moisture and air

- The result? A chemical cocktail that eats into the metal

Fact | Positive terminals corrode faster due to higher current flow. If you see buildup there, it’s not random; it’s physics.

Terminal corrosion usually starts at the clamp and creeps into the cable. You’ll spot it as:

- White powder (lead sulfate)

- Green-blue crust (copper sulfate)

- Blackened or oily residue (acid leakage)

Ignore it, and you’re not just risking poor starts; you’re inviting full-blown battery terminal failure. And once corrosion reaches the cable, cleaning won’t cut it. You’ll need replacements. So yes, those little clamps matter. A lot. And they deserve more attention than most drivers give them.

How to Spot Corroded Car Battery Terminals Before They Wreck Your Day

It usually starts with something small. Maybe your car takes a second longer to start. Maybe the headlights flicker when you hit the brakes. You ignore it until one morning, nothing works. That’s how car battery terminals warn you. Quietly. Then suddenly. Corrosion doesn’t hide. It shows up as:

- White powder around the clamps (lead sulfate)

- Green or bluish buildup on copper terminals (copper sulfate)

- Rusty or oily residue near the battery case

These are not just cosmetic issues. They’re battery corrosion symptoms, and they block current flow. That means poor conductivity, weak ignition, and erratic electronics. You might notice:

- Slow engine start, especially in the morning

- Dim headlights, even with a full battery

- Dashboard alerts that come and go without reason

Sometimes, the corrosion spreads into the cable itself. At that point, cleaning won’t help; you’ll need to replace the terminal or the entire cable. Car battery terminals don’t fail overnight. They give signs. But only if you’re looking. And in Dubai’s heat, those signs show up faster than you think.

Why Corrosion Doesn’t Stay on the Terminals?

Here’s the thing: car battery terminals don’t corrode in isolation. Once corrosion starts, it spreads. Slowly at first. Then aggressively. And it doesn’t care what it touches. That white or green buildup you see? It’s not just sitting there. It’s creeping into the cables, eating into the connectors, and sometimes reaching the fuse box. We’ve seen cases where the corrosion traveled a full foot down the cable, turning copper strands into brittle junk.

Fact | Corrosion can cause voltage drops that confuse your car’s ECU, triggering false alerts or disabling systems entirely.

The real danger? Electrical shorts. When corrosion bridges connections that shouldn’t touch, it can fry circuits. That’s not just inconvenient, it’s expensive. We’ve replaced starter motors and alternators that failed because of ignored terminal contamination. And just like corrosion spreads quietly under the hood, small cracks in your windshield also spread rapidly in UAE conditions, often turning into full replacements when ignored.Here’s how it spreads:

- Acid vapor leaks from the battery

- It reacts with metal and moisture

- That reaction travels through exposed wiring

Car battery terminals are the entry point. Once compromised, the damage doesn’t stop there. If your cables feel stiff or look discolored, it’s not just age; it’s corrosion doing its thing. And in Dubai’s climate, with heat pushing battery gases into overdrive, the system-wide impact happens faster than most drivers expect. Catch it early, or pay for it later.

Root Causes of Car Battery Terminal Corrosion

Corrosion doesn’t just happen. It’s triggered. And once it starts, it rarely stays put. The real issue with car battery terminals isn’t just the crusty buildup; it’s what’s causing it in the first place. Let’s break it down.

- Overcharging and Undercharging

Too much voltage from a faulty alternator? That pushes excess current through the terminals, heating them and releasing more hydrogen gas. Not enough charge? That leads to acid stratification, which also encourages corrosion. Either way, the terminals suffer.

Tip | Ideal alternator output should stay between 13.8V and 14.4V. Anything above or below? Time to check your charging system.

- Electrolyte Leakage

Old batteries tend to leak. Sometimes it’s from overfilling, sometimes just age. That electrolyte, a mix of sulfuric acid and water, creeps up and reacts with the metal clamps. The result? Corrosion causes, like lead sulfate and copper sulfate, start forming. - Environmental Factors

Dubai’s climate doesn’t help. High humidity, sudden temperature swings, and dust storms all accelerate corrosion. Moisture reacts with battery gases, forming acidic compounds that eat into the terminals. - Battery Age

After about 3–4 years, most batteries start showing signs of wear. Terminal corrosion is often the first red flag. If your battery’s past its prime, the terminals are likely already compromised.

Car battery terminals are exposed, reactive, and constantly under stress. Understanding these root causes isn’t just technical, it’s practical. Fix the source, and you stop the spread. Ignore it, and you’ll be chasing electrical gremlins across your entire system.

How to Fix Corroded Car Battery Terminals Step by Step

Before you grab a wrench and dive under the hood, pause. Car battery terminals carry live current. Mishandling them can cause sparks, or worse. So first, safety.

Start with these precautions

- Turn off the engine

- Remove the key

- Disconnect the negative terminal first, then the positive

- Wear gloves and safety glasses, acid residue is no joke

Tip | Never touch both terminals at once with metal tools. That’s how you short a battery.

Now, let’s get into the corrosion removal process. You’ll need:

- A small wire brush

- A wrench (usually 10mm)

- A bowl of baking soda solution (1 tablespoon baking soda in 1 cup water)

- Clean cloths or paper towels

Step-by-step terminal cleaning

Here are the proper steps involved in terminal cleaning.

- Mix the baking soda and water. It neutralizes acid buildup.

- Dip the brush into the solution and scrub the car battery terminals. Focus on the clamp and the post.

- Let it fizz. That’s the acid reacting.

- Wipe everything dry with a clean cloth.

- Inspect for damage, cracks, melted plastic, or rusted clamps mean replacement.

- Reconnect the terminals: positive first, then negative. Tighten them snug, not overly tight.

Fact | Loose terminals cause voltage drops. That leads to flickering lights and weak starts.

After cleaning, start the car. If it fires up strong and the electronics behave, you’ve done it right. If not, the corrosion may have spread deeper, into the cables or connectors. Electrical issues often show up alongside cooling-system problems as well, for example, a radiator fan that stops working can cause overheating, voltage strain, and further damage if not diagnosed early.

Car battery terminals don’t need fancy tools. Just patience, the right steps, and a little elbow grease. DIY battery maintenance like this can save you from bigger repairs down the line. But if the buildup returns fast, it’s time to check the battery itself. Something’s feeding the corrosion.

When DIY Isn’t Enough | Professional Battery Terminal Cleaning Services

You’ve scrubbed the terminals, rinsed with baking soda, tightened the clamps, and yet, the car still hesitates. That’s when it’s time to stop guessing and call in a battery service expert.

Corrosion doesn’t always stay on the surface. Sometimes it’s inside the cable, under the insulation, or creeping toward the fuse box. A quick clean won’t fix that. Professional car battery terminal cleaning goes deeper. We don’t just brush off buildup; we inspect voltage drops, test conductivity, and check for hidden damage. Here’s what a full-service package usually includes:

- Expert inspection of terminals, cables, and connectors

- Corrosion treatment using neutralizers and protectants

- Terminal replacement if clamps are worn or damaged

- Battery health report and recommendations

Dubai’s heat speeds up corrosion. If you’re dealing with repeat buildup or electrical glitches, DIY might not cut it. A trusted auto repair shop can spot what you can’t, and fix it before it spreads. Car battery terminals are small, but the problems they cause aren’t. Let a service provider handle it right the first time.

Preventive Measures to Protect Car Battery Terminals

You’ve cleaned the terminals, tightened the clamps, and the car starts like it should. Great. But if you stop there, you’re just buying time. In Dubai’s heat, corrosion doesn’t wait; it returns. Unless you block it. Car battery terminals are exposed to moisture, acid vapor, and heat. That’s a perfect storm for corrosion. So prevention isn’t optional, it’s maintenance. Here’s what works:

- Anti-corrosion spray | A quick coat after cleaning forms a barrier against acid fumes.

- Terminal grease | Thick, non-conductive, and designed to seal out moisture.

- Terminal protectors | Foam washers soaked in corrosion-resistant compound, cheap, effective, and easy to install.

Tip | Always apply protectants after cleaning, not before. Otherwise, you’re sealing in the problem.

Routine battery maintenance matters too. Every few months:

- Check terminal tightness. Loose clamps spark and corrode faster.

- Inspect for moisture or acid stains.

- Run a voltage check; low readings can mean internal leaks or charging issues.

Fact | A battery reading below 12.4V at rest may already be compromised.

For drivers who prefer expert help, professional car battery terminal cleaning in Dubai ensures corrosion is removed properly and hidden electrical issues are detected before they spread.

And don’t forget the basics. Keep the battery tray clean. Make sure the hold-down bracket isn’t too tight; it can crack the case and cause leaks. Car battery terminals don’t need daily attention. But ignoring them for a year? That’s how corrosion wins. A few minutes of prevention beats hours of diagnostics and replacement. Especially in a climate where batteries work overtime just to survive.

When to Replace Car Battery Terminals Entirely?

Sometimes, cleaning just delays the inevitable. If your car battery terminals are cracked, warped, or the clamps don’t grip properly, even after tightening, it’s time for terminal replacement. Here’s what to look for:

- Damaged clamps that won’t hold tension

- Worn connectors with visible rust or pitting

- Acid stains that keep returning after cleaning

Fact | Repeated corrosion often means the terminal material has degraded. No amount of brushing will restore conductivity.

Replacement process is straightforward:

- Disconnect the battery safely

- Remove old terminals

- Install new ones compatible with your battery post type (top post or side post)

- Apply anti-corrosion grease before reconnecting

Estimated cost for terminal replacement in Dubai: AED 50–120, depending on material and labor. This is an estimation cost; for exact pricing, contact us.

Service timeline? Usually under 30 minutes. But if corrosion has spread into the cables, expect longer diagnostics. Car battery terminals are small, but once they fail, they drag down the entire system. If cleaning feels like a temporary fix every time, it probably is. Better to replace and reset than chase electrical issues across your dashboard.

How Corroded Car Battery Terminals Damage More Than Just the Battery

Corrosion doesn’t stop at the clamps. Once car battery terminals start breaking down, the ripple effect hits everything connected to them. And that’s where the real electrical damage begins.

Your starter motor relies on clean, uninterrupted current. Corroded terminals choke that flow, causing slow cranks or no start at all. The alternator? It works harder to compensate, which shortens its lifespan. Even the fuse box isn’t safe; voltage drops can trigger false errors or blow fuses without warning.

- Starter Motor

Corroded terminals restrict current flow, causing weak or delayed ignition. Over time, the starter motor strains to compensate, leading to premature wear or complete failure. - Alternator

Voltage irregularities from poor terminal contact force the alternator to overwork. This can shorten its lifespan and cause charging issues across the system. - Battery Cables

Corrosion often creeps into the cable itself, damaging the copper strands inside. This leads to resistance, overheating, and eventual cable failure. - Fuse Box & Relays

Voltage drops and electrical noise from corroded terminals can trigger false signals, blow fuses, or cause relays to misfire. That means random system shutdowns or warning lights. - ECU (Engine Control Unit)

Inconsistent voltage can confuse the ECU, leading to erratic behavior, poor fuel mapping, misfires, or unnecessary fault codes. - Lighting & Infotainment Systems

Dim headlights, flickering interior lights, and glitchy infotainment screens often trace back to poor terminal conductivity. - Transmission Control Module (TCM)

Voltage instability can affect gear shifting logic, especially in modern vehicles with electronically controlled transmissions.

Don’t Wait- Fix Car Battery Terminals Before They Spread

Corrosion doesn’t pause. Once it starts, it spreads into cables, connectors, and systems that cost far more to fix. Car battery terminals are the first line of defense, and ignoring them is how electrical health breaks down. You’ve seen the signs. You’ve read the risks. Now’s the time to act. Whether it’s a simple cleaning or a full corrosion fix, we’re here to help. Schedule your battery care service, get ahead of the damage, and keep your vehicle running without surprises.

Book your inspection now. Contact our service team.